Image processing

3D Imaging, based on x-ray and neutron technologies, is a non-destructive technique that generates 3D maps of the internal structure of materials and components.

Synchrotrons (for x-rays) and neutron facilities provide some exceptional instruments to capture high resolution CT data with extremely high acquisition rates, using state-of-the art sample motion stages and detectors. The analysis of the images produced however is becoming progressively more challenging due to the sheer size of the data that is generated.

It is also often the case that researchers collect data at different facilities to take advantage of specific instrument characteristics and specifications; however, this can pose difficulties in integrating the data into a coherent framework useful to extract the structural information that is required.

Here is where we can help. We develop custom scripts and algorithms to help make sense of your CT data. We generate a bespoke workflow to transform raw imaging data into quantitative analysis of your samples, for instance composite analysis, porosity evaluation, material segmentation, etc.

Check out our most recent publications.

Our capabilities

CT data processing

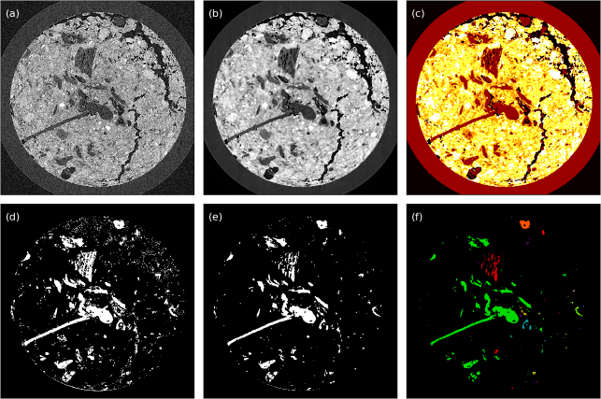

- Phase-retrieval algorithms for contrast enhancement and noise reduction in low-absorbing samples

- Misalignment and motions correction and normalisation

- Detector-artefacts (for instance ring artifact) compensation

Post-reconstruction data treatment

- Data processing and analysis of the reconstructed tomographic volumes

- Feature extraction

- Composite analysis

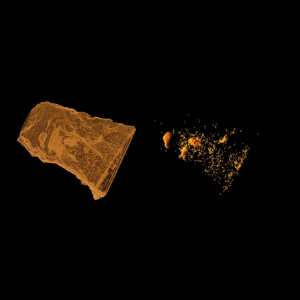

- Segmentation and rendering

- Quantitative analysis of segmented data.

- Service for additive manufacturing: quantitative comparisons between CAD models (nominal design) and CT scans (actual realisation) of the same part.

- Assistance in writing project proposals for beam time at national and international facilities involving imaging or tomography.

Our process

Feasibility/Quote

We will work with you to produce a free feasibility study and finalise the quote for your project.

Project work and reporting

We will develop the data processing workflow as decided. Larger projects are usually broken down into milestones with progress meetings held are necessary. Imaging data and reports are generated according to your needs and specification.

Recent case study

Porosity analysis of concrete: An investigation using x-ray tomography and volume rendering

We develop tailored algorithms to extract quantitative porosity analysis from imaging data of rocks, concrete, metal components produced by additive manufacturing, etc. Our method is based on the segmentation and labelling of individual pores in 3D, so that the full distribution of pore volume versus pore number (histogram) can be derived from the data.